Contents

4.1.1 OPERATION PHASE MONITORING

4.2.1 OPERATION PHASE MONITORING

4.3.1 OPERATION PHASE MONITORING

Annex

B project

organisation chart with contact details

Annex

C implementation

schedule of mitigation measures

Annex

E environmental

complaint, environmental summons and prosecution log

List of Tables

Table 2.1 Summary of Activities Undertaken in the Reporting Period

Table 2.2 Summary of Environmental Licensing, Notification and Permit Status

Table 3.1 Sampling and Laboratory Analysis Methodology

Table 3.2 Emission Limit for CAPCS Stack

Table 3.3 Emission Limit for CHP Stack

Table 3.4 Emission Limit for ASP Stack

Table 3.5 Emission Limit for Standby Flaring Gas Unit (1)

Table 3.6 Odour Intensity Level

Table 3.7 Action and Limit Levels for Odour Nuisance

Table 3.8 Event and Action Plan for Odour Monitoring

Table 4.1 Hourly Average of Parameters Recorded for CAPCS

Table 4.2 Hourly Average of Parameters Recorded for CHP 1

Table 4.3 Hourly Average of Parameters Recorded for CHP 2

Table 4.4 Hourly Average of Parameters Recorded for CHP 3

Table 4.5 Hourly Average of Parameters Recorded for ASP

Table 4.6 Hourly Average of Parameters Recorded for the Standby Flaring Gas Unit

Table 4.7 Quantities of Waste Generated from the Operation of the Project

EXECUTIVE SUMMARY

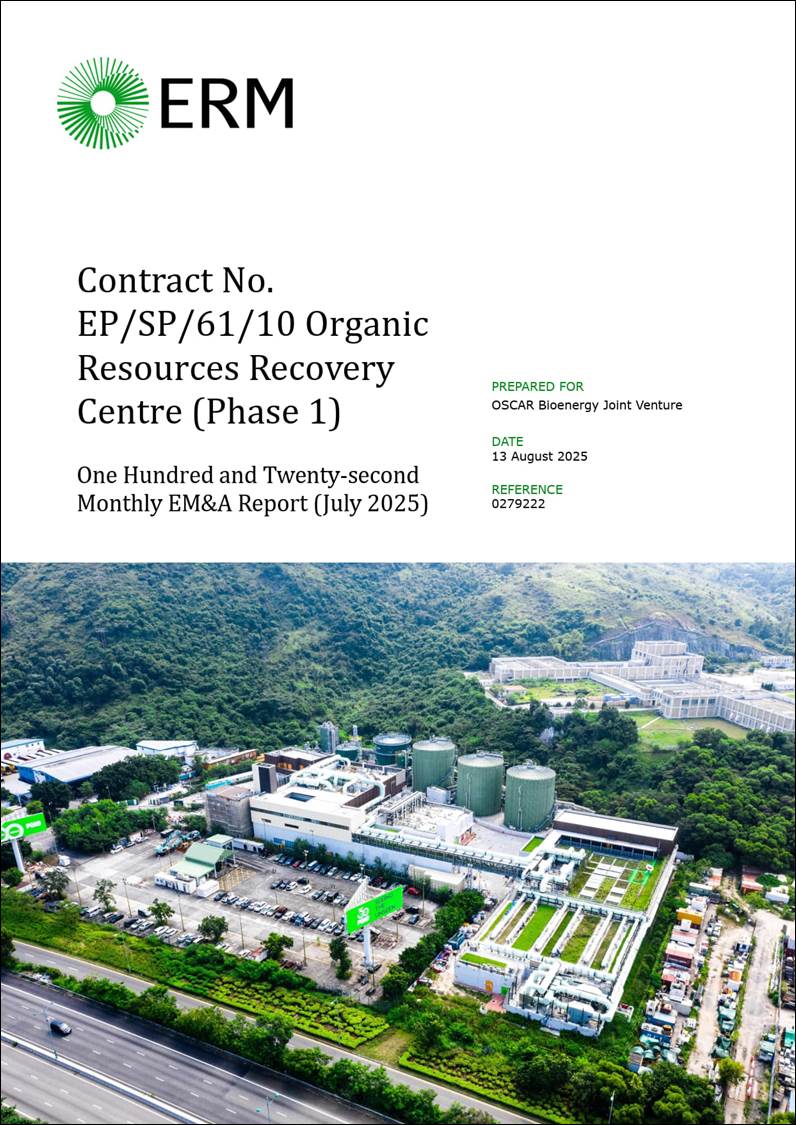

The construction works of No. EP/SP/61/10 Organic Resources Recovery Centre Phase 1 (the Project) commenced on 21 May 2015. This is the 122nd Monthly Environmental Monitoring and Audit (EM&A) report presenting the EM&A works carried out during the period from 1 to 31 July 2025 in accordance with the EM&A Manual.

Summary of works undertaken during

the reporting month

Works undertaken in the reporting month included:

· Operation of the Project, including organic waste reception, operation of the pre-treatment facilities, anaerobic digesters, composting facilities, air pollution control systems, on-line emission monitoring system for the Centralised Air Pollution Control Unit (CAPCS), Co-generation Units (CHP)s and Ammonia Stripping Plant (ASP), and the wastewater treatment plant.

Environmental monitoring and audit

progress

air

Quality monitoring

Non-compliances of emission limits were recorded at CAPCS, CHPs, ASP and Standby Flaring Gas Unit during the reporting period.

ODOUR

PATROL

During the reporting period, one (1) Action Level exceedance (detection of Odour Intensity Level 2) was recorded during the independent odour patrol at Location 2 (Tipping Hall) on 15 July 2025.

In accordance with the Event and Action Plan for Odour Monitoring (see Table 3.8), an ad-hoc odour patrol was arranged on 28 July 2025 to confirm the findings, which identified one (1) Level 2 exceedance in Round 1, constituting an exceedance of the Limit Level under the EM&A Manual. A further patrol was conducted in Round 2 with no exceedance identified.

Waste

Management

Waste generated from the operation of the Project includes chemical waste, waste generated from pre-treatment process, and general refuse.

8,000 litres of chemical waste were disposed of at CWTC in July 2025.

657.84 tonnes of waste generated from pre-treatment process from the operation of the Project were disposed of at landfill. Among the waste generated from pre-treatment process from the operation of the Project, no metals, papers/cardboard packing or plastics were sent to recyclers for recycling during the reporting period.

Around 2.995 tonnes of general refuse from the operation of the Project were disposed of at landfill. Among the general refuse from the operation of the Project, 0.027 tonnes of papers/cardboard packing were sent to recyclers for recycling during the reporting period. No metals or plastics were sent to recyclers for recycling during the reporting period.

findings of Environmental site audit

A summary of the monitoring activities undertaken in this reporting period is listed below:

· Joint Environmental Site Inspections 1 time

1 monthly joint environmental site inspection was carried out by the representatives of the Contractor and the Monitoring Team (MT). The Independent Environmental Checker (IEC) was also present at the joint inspection on 29 July 2025.

The environmental control/ mitigation measures (related to air quality, water quality, waste (including land contamination prevention), hazard-to-life and landscape and visual) recommended in the approved EIA Report and the EM&A Manual were properly implemented by the Contractor during the reporting month.

Environmental exceedance/ non-conformance, complaint, summons and

prosecution

Exceedances of the air emission limits for CAPCS, CHPs, ASP and Standby Flaring Gas Unit, as well as exceedances against the Action Level for odour nuisance were recorded during the reporting period.

No complaint was received during the reporting period.

future key issues

Activities to be undertaken in the next reporting month include:

· Implementation of various optimization measures in wastewater treatment plant.

1.

Introduction

ERM-Hong Kong, Limited (ERM) was appointed by OSCAR Bioenergy Joint Venture (the Contractor) as the Environmental Team (ET) to undertake the construction Environmental Monitoring and Audit (EM&A) programme for the Contract No. EP/SP/61/10 of Organic Waste Treatment Facilities Phase I, which the project name has been updated to Organic Resources Recovery Centre (Phase I) (the Project) since November 2017. ERM was also appointed by the Contractor to undertake the operation EM&A programme starting 1 March 2019.

1.1 Purpose of the report

This is the 122nd EM&A report which summarises the monitoring results and audit findings for the EM&A programme during the reporting period from 1 to 31 July 2025.

1.2 structure of the report

The structure of the report is as follows:

Section 1: Introduction

It details the scope and structure of the report.

Section 2: Project

Information

It summarises the background and scope of the Project, site description, project organisation and status of the Environmental Permits (EP)/licences.

Section 3: Environmental Monitoring and

Audit Requirements

It summarises the environmental monitoring requirements including monitoring parameters, programmes, methodologies, frequency, locations, Action and Limit Levels, Event/Action Plans, as well as environmental audit requirements as recommended in the EM&A Manual and approved EIA report.

Section 4: Monitoring

Results

It summarises monitoring results of the reporting period.

Section 5: Site Audit

It summarises the audit findings of the environmental as well as landscape and visual site audits undertaken within the reporting period.

Section 6: Environmental

Non-conformance

It summarises any exceedance of environmental performance standard, environmental complaints and summons received within the reporting period.

Section 7: Further Key

Issues

It summarises the impact forecast for the next reporting month.

Section 8: Conclusions

2.

project information

2.1 background

The Organic Resources Recovery Centre (ORRC) Phase I development (hereinafter referred to as the Project) is to design, construct and operate a biological treatment facility with a capacity of about 200 tonnes per day and convert source-separated organic waste from commercial and industrial sectors (mostly food waste) into compost and biogas through proven biological treatment technologies. The location of the Project site is shown in Annex A.

An Environmental Permit (EP) (No. EP-395/2010) was issued by the DEP to the EPD (Project Team), the EP was varied on 18 March 2013 (No. EP-395/2010/A) and 21 May 2013 (No. EP-395/2010/B. A Further EP (No. FEP-01/395/2010/B) was issued by the DEP to the OSCAR on 16 February 2015. The latest EPs, Nos. EP-395/2010/C and FEP-01/395/2010/C, were issued by the DEP on 21 December 2015.

ERM-Hong Kong, Ltd (ERM) has been appointed by OSCAR as the Monitoring Team (MT) for the operation phase EM&A programme for the implementation of the EM&A programme in accordance with the requirements of the EP and the approved EM&A Manual.

2.2

general site description

The Project Site is located at Siu Ho Wan in North Lantau with an area of about 2 hectares. The layout of the Project Site is illustrated in Annex A. The facility received an average of 104.65 tonnes and treated an average of 83.43 tonnes of source separated organic waste per day during the reporting month.

2.3 major activities undertaken

A summary of the major activities undertaken in the reporting period is shown in Table 2.1.

Table 2.1 Summary of Activities Undertaken in the Reporting Period

|

Activities Undertaken in the Reporting Period |

|

· Systems being operated waste reception, pre-treatment, CAPCS extraction, the digesters, the centrifuge, the composting tunnels, the de-sulphurisation, the CHPs, the ASP, and the biological wastewater treatment plant (104.65 t/d SSOW received). |

2.4 project organisation and management

structure

The project organisation chart and contact details are shown in Annex B.

2.5 status of environmental approval

documents

A summary of the valid permits, licences, and/or notifications on environmental protection for this Project is presented in Table 2.2.

Table 2.2 Summary of Environmental Licensing, Notification and Permit Status

|

Permit/ Licences/ Notification |

Reference |

Validity Period |

Remarks |

|

Environmental Permit |

FEP-01/395/2010/C |

Throughout the Contract |

Permit granted on 21 December 2015 |

|

Effluent Discharge Licence |

WT00038391-2021 |

7 July 2021 30 June 2026 |

Approved on 7 July 2021 |

|

Chemical Waste Producer Registration |

WPN 5213-961-O2231-02 |

Throughout the implementation of the Project |

Approved on 10 November 2017 |

|

Waste Disposal Billing Account |

Account number: 702310 |

Throughout the Contract |

- |

3.

ENVIRONMENTAL MONITORING AND AUDIT REQUIREMENTS

3.1 Environmental monitoring

The air quality (including odour) monitoring to be carried out during the commissioning and operation phase of the Project are described below. Although water quality monitoring is not required for the operation phase under the EM&A programme, there are water quality monitoring requirement under the Water Discharge Licence of the plant under the Water Pollution Control Ordinance (WPCO). As part of this EM&A programme, the monitoring results will be reviewed to check the compliance with the WPCO requirements.

3.1.1 AIR QUALITY

According to the EM&A Manual and EP requirements, stack monitoring is required during the commissioning and operation phase of the Project.

On-line monitoring using continuous environmental monitoring system (CEMS) shall be carried out for the Centralised Air Pollution Unit (CAPCS), cogeneration units (CHPs) and the ammonia stripping plant (ASP) during the commissioning and operation phase. The most recent sensor calibration for the CAPCS system for VOCs and H2S were both carried out in January 2025. The most recent span calibrations for the CEMS systems (CHP1, CHP2, CHP3, and ASP) were carried out on 28 May 2024. Annual CAPCS calibration was carried out on 15 and 30 October 2024.

The monitoring data is transmitted instantaneously to EPD (Regional Office) by telemetry system.

When the on-line monitoring for certain parameter cannot be undertaken, monitoring will be carried out using the following methodology approved by the EPD.

Table 3.1 Sampling and Laboratory Analysis Methodology

|

Parameters |

Method |

Stacks to be Monitored |

|

Gaseous and vaporous organic substances (including methane) |

USEPA Method 18 |

· CAPCS · CHP · ASP |

|

Particulate |

USEPA Method 5 |

· CAPCS · CHP · ASP |

|

Carbon monoxide (CO) |

USEPA Method 10 |

· CHP · ASP |

|

Nitrogen oxides (NOx) |

USEPA Method 7E |

· CHP · ASP |

|

Sulphur dioxide (SO2) |

USEPA Method 6 |

· CHP · ASP |

|

Hydrogen chloride (HCl) |

USEPA Method 26A |

· CHP · ASP |

|

Hydrogen fluoride (HF) |

USEPA Method 26A |

· CHP · ASP |

|

Oxygen (O2) |

USEPA Method 3A |

· CAPCS · CHP · ASP |

|

Velocity and Volumetric Flow |

USEPA Method 2 |

· CAPCS · CHP · ASP |

|

Ammonia (NH3) |

USEPA CTM 027 |

· ASP |

|

Odour (including NH3 and H2S) |

EN 13725 |

· ASP |

|

Water vapour content (continuous measurement of the water vapour content should not be required if the sample exhaust gas is dried before the emissions are analysed) |

USEPA Method 4 |

· CAPCS · CHP · ASP |

|

Temperature |

USEPA Method 4 |

· CAPCS · CHP · ASP |

With reference to the EM&A Manual, the air emission of the stacks shall meet the following emission limits as presented in Tables 3.2 to 3.5.

Table 3.2 Emission Limit for CAPCS Stack

|

Parameter |

Emission Level (mg/Nm3) (a) |

|

VOCs (including methane) |

680 |

|

Dust (or Total Suspended Particulates (TSP)) |

6 |

|

Odour (including NH3 & H2S) |

220 (b) |

|

Notes: (a) Hourly average concentration (b) The odour unit is OU/Nm3 |

|

Table 3.3 Emission Limit for CHP Stack

|

Parameter |

Maximum Emission Level (mg/Nm3) (a) (b) |

|

Dust (or Total Suspended Particulates) |

15 |

|

Carbon Monoxide |

650 |

|

NOx |

300 |

|

SO2 |

50 |

|

NMVOCs (c) |

150 |

|

VOCs (including methane) (d) |

1,500 |

|

HCl |

10 |

|

HF |

1 |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 6% and dry basis. (b) Hourly average concentration (c) NMVOCs should be monitored by gas sampling and laboratory analysis at an agreed interval. For the first 12 months (starting from August 2019), monitoring should be carried out at quarterly intervals. The monitoring frequency should then be reduced to half-yearly for next 12 months (starting from August 2020). The monitoring of NMVOCs ended in August 2021. (d) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. |

|

Table 3.4 Emission Limit for ASP Stack

|

Parameter |

Maximum Emission Level (mg/Nm3) (a) (b) |

|

Dust (or Total Suspended Particulates) |

5 |

|

Carbon Monoxide |

100 |

|

NOx |

200 |

|

SO2 |

50 |

|

VOCs (including methane) (c) |

20 |

|

NH3 |

35 |

|

HCl |

10 |

|

HF |

1 |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 11% and dry basis. (b) Hourly average concentration (c) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. |

|

Table 3.5 Emission Limit for Standby Flaring Gas Unit ([1])

|

Parameter |

Maximum Emission Level (mg/Nm3) (a) (b) |

|

Dust (or Total Suspended Particulates) |

5 |

|

Carbon Monoxide |

100 |

|

NOx |

200 |

|

SO2 |

50 |

|

VOCs (including methane) (c) |

20 |

|

HCl |

10 |

|

HF |

1 |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 11% and dry basis. (b) Hourly average concentration (c) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. |

|

3.1.2 ODOUR

To determine the effectiveness of the proposed odour mitigation measures and to ensure that the operation of the ORRC1 will not cause adverse odour impacts, odour monitoring of the CAPCS stack (see Section 3.1.1), and odour patrol will be carried out.

Odour patrol shall be conducted by independent trained personnel/ competent persons in summer months (i.e. from July to September) for the first two operational years of ORRC1 at monthly intervals along an odour patrol route at the Project Site boundary as shown in Annex A ([2]).

The perceived odour intensity is divided into 5 levels. Table 3.6 describes the odour intensity for different levels.

Table 3.6 Odour Intensity Level

|

Level |

Odour Intensity |

|

0 |

Not detected. No odour perceived or an odour so weak that it cannot be easily characterised or described |

|

1 |

Slight identifiable odour, and slight chance to have odour nuisance |

|

2 |

Moderate identifiable odour, and moderate chance to have odour nuisance |

|

3 |

Strong identifiable, likely to have odour nuisance |

|

4 |

Extreme severe odour, and unacceptable odour level |

Table 3.7 shows the action level and limit level to be used for odour patrol. Should any exceedance of the action and limit levels occur, actions in accordance with the event and action plan in Table 3.8 should be carried out.

Table 3.7 Action and Limit Levels for Odour Nuisance

|

Parameter |

Action Level |

Limit Level |

|

Odour Nuisance (from odour patrol) |

When one documented compliant is received (a), or Odour Intensity of 2 is measured from odour patrol. |

Two or more documented complaints are received (a) within a week; or Odour intensity of 3 or above is measured from odour patrol. |

|

Note: (a) Once the complaint is received by the Project Proponent (EPD), the Project Proponent would investigate and verify the complaint whether it is related to the potential odour emission from the ORRC1 and its on-site wastewater treatment unit. |

||

Table 3.8 Event and Action Plan for Odour Monitoring

|

Event |

Action by Person-in-charge of Odour Monitoring: |

Action by Project Proponent: (a) |

|

Action Level |

||

|

Exceedance of action level (Odour Patrol) |

1. Identify source/reason of exceedance; 2. Repeat odour patrol to confirm finding. |

1. Carry out investigation to identify the source/reason of exceedance. Investigation should be completed within 2 weeks; 2. Rectify any unacceptable practice; 3. Implement more mitigation measures if necessary; 4. Inform Drainage Services Department (DSD) or the operator of the Siu Ho Wan Sewage Treatment Works (SHWSTW) if exceedance is considered to be caused by the operation of the SHWSTW. 5. Inform North Lantau Refuse Transfer Station (NLTS) operator if exceedance is considered to be caused by the operation of NLTS. |

|

Exceedance of action level (Odour Complaints) |

1. Identify source/reason of exceedance; 2. Carry out odour patrol to determinate odour intensity. |

1. Carry out investigation and verify the complaint whether it is related to potential odour emission from the nearby SHWSTW; 2. Carry out investigation to identify the source/reason of exceedance. Investigation should be completed within 2 weeks; 3. Rectify any unacceptable practice; 4. Implement more mitigation measures if necessary; 5. Inform DSD or the operator of the SHWSTW if exceedance is considered to be caused by the operation of the SHWSTW. 6. Inform NLTS operator if exceedance is considered to be caused by the operation of NLTS. |

|

Limit Level |

||

|

Exceedance of limit level |

1. Identify source/reason of exceedance; 2. Inform EPD; 3. Repeat odour patrol to confirm findings; 4. Increase odour patrol frequency to bi-weekly; 5. Assess effectiveness of remedial action and keep EPD informed of the results; 6. If exceedance stops, cease additional odour patrol. |

1. Carry out investigation to identify the source/reason of exceedance. Investigation should be completed within 2 weeks; 2. Rectify any unacceptable practice; 3. Formulate remedial actions; 4. Ensure remedial actions properly implemented; 5. If exceedance continues, consider what more/enhanced mitigation measures should be implemented; 6. Inform DSD or the operator of the SHWSTW if exceedance is considered to be caused by the operation of the SHWSTW. |

|

Note: (a) Project Proponent shall identify an implementation agent. |

||

3.2 SITE AUDIT

Environmental mitigation measures (related to air quality, water quality, waste, land contamination, hazard-to-life, and landscape and visual) to be implemented during the operation phase of the Project are recommended in the approved EIA Report and EM&A Manual and are summarised in Annex C. Monthly site audits for operation phase will be carried out to check the implementation of these measures.

4.

monitoring results

4.1 air quality

4.1.1 OPERATION PHASE MONITORING

The concentrations of concerned air pollutants emitted from the stacks of the CAPCS, CHPs, ASP, and the Standby Flaring Gas Unit during the reporting period are monitored on-line by the continuous environmental monitoring system (CEMS).

With reference to the emission limits in Tables 3.2, 3.3, 3.4, and 3.5, the hourly average concentrations and the number of exceedances of the concerned air emissions monitored for the CAPCS, CHPs, ASP and the Standby Flaring Gas Unit during the reporting period are presented in Tables 4.1 to 4.6.

It should be noted that measurements recorded under abnormal operating conditions, e.g. start up and stopping of stacks, unstable operation, test runs, maintenance and interference of sensor, signal communication issues are disregarded.

Table 4.1 Hourly Average of Parameters Recorded for CAPCS

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) |

Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

VOCs (including methane) (a) |

0 1 |

680 |

Nil |

Nil |

|

Dust (or TSP) |

0 0 |

6 |

Nil |

Nil |

|

Odour (including NH3 & H2S) (b) |

0 1,285 |

220 |

Identified (c) |

System unstable (e.g. low efficiency) |

|

Notes: (a) The VOCs emission limit includes methane as biogas is adopted, as fuel in the combustion process. (b) The odour unit is ou/Nm3. (c) Dates with Total Odour exceedances (number of exceedances on that day) were identified on 18(24), 19(24), 20(10), 21(5), 22(16), 23(15), 24(17), 25(17), 26(7), 27(2) and 30(1) July 2025. |

||||

Table 4.2 Hourly Average of Parameters Recorded for CHP 1

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) |

Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

Dust (or TSP) |

0 9 |

15 |

Nil |

Nil |

|

Carbon Monoxide |

0 78 |

650 |

Nil |

Nil |

|

NOx |

0 516 |

300 |

Identified (c) |

System unstable (e.g. low efficiency) |

|

SO2 |

0 53 |

50 |

Identified (d) |

System unstable (e.g. low efficiency) |

|

VOCs (including methane) (b) |

0 540 |

1,500 |

Nil |

Nil |

|

HCl |

0 1 |

10 |

Nil |

Nil |

|

HF |

0 1 |

1 |

Nil |

Nil |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 6% and dry basis. (b) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. (c) Dates with NOx exceedances (number of exceedances on that day) were identified on 1(3), 2(7), 3(24), 4(21), 5(11), 6(2), 7(7), 8(24), 9(9), 10(11), 11(13), 12(24), 13(24), 14(21), 15(24), 16(24), 17(24), 18(24), 19(24), 20(4), 22(2), 23(13), 24(20), 25(2), 26(5), 27(4), 28(4), 29(7), 30(2) and 31(9) July 2025. (d) Date with SO2 exceedance (number of exceedance on that day) was identified on 18(1) July 2025. |

||||

Table 4.3 Hourly Average of Parameters Recorded for CHP 2

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) |

Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

Dust (or TSP) |

0 3 |

15 |

Nil |

Nil |

|

Carbon Monoxide |

0 95 |

650 |

Nil |

Nil |

|

NOx |

0 355 |

300 |

Identified (c) |

System unstable (e.g. low efficiency) |

|

SO2 |

0 23 |

50 |

Nil |

Nil |

|

VOCs (including methane) (b) |

0 1,011 |

1,500 |

Nil |

Nil |

|

HCl |

0 8 |

10 |

Nil |

Nil |

|

HF |

0 0 |

1 |

Nil |

Nil |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 6% and dry basis. (b) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. (c) Dates with NOx exceedances (number of exceedances on that day) were identified on 1(6), 2(13), 22(1), 27(6) and 28(6) July 2025. |

||||

Table 4.4 Hourly Average of

Parameters Recorded for CHP 3

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) |

Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

Dust (or TSP) |

0 6 |

15 |

Nil |

Nil |

|

Carbon Monoxide |

0 81 |

650 |

Nil |

Nil |

|

NOx |

0 489 |

300 |

Identified (c) |

System unstable (e.g. low efficiency) |

|

SO2 |

0 38 |

50 |

Nil |

Nil |

|

VOCs (including methane) (b) |

0 922 |

1,500 |

Nil |

Nil |

|

HCl |

0 7 |

10 |

Nil |

Nil |

|

HF |

0 1 |

1 |

Nil |

Nil |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 6% and dry basis. (b) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. (c) Dates with NOx exceedances (number of exceedances on that day) were identified on 1(18), 2(17), 3(13), 4(3), 5(20), 6(23), 7(8), 8(1), 12(9), 13(6), 17(1), 18(2), 19(3), 22(7), 23(11), 24(10), 25(23), 26(21), 27(20), 28(20), 29(15), 30(9) and 31(6) July 2025. |

||||

Table 4.5 Hourly Average of Parameters Recorded for ASP

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) |

Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

Dust (or TSP) |

0 5 |

5 |

Nil |

Nil |

|

Carbon Monoxide |

0 1,543 |

100 |

Identified (c) |

System unstable (e.g. low efficiency) |

|

NOx |

0 998 |

200 |

Identified (d) |

System unstable (e.g. low efficiency) |

|

SO2 |

0 234 |

50 |

Identified (e) |

System unstable (e.g. low efficiency) |

|

VOCs (including methane) (b) |

0 3,415 |

20 |

Identified (f) |

System unstable (e.g. low efficiency) |

|

NH3 |

0 193 |

35 |

Identified (g) |

System unstable (e.g. low efficiency) |

|

HCl |

0 23 |

10 |

Identified (h) |

System unstable (e.g. low efficiency) |

|

HF |

0 5 |

1 |

Identified (i) |

System unstable (e.g. low efficiency) |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 6% and dry basis. (b) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. (c) Dates with CO exceedances (number of exceedances on that day) were identified on 1(2), 2(5), 3(6), 4(2), 5(5), 6(5), 7(1), 10(1), 12(1), 14(2), 17(2), 18(3), 19(4), 20(2), 23(2) and 24(3) July 2025. (d) Dates with NOx exceedances (number of exceedances on that day) were identified on 1(24), 2(24), 3(24), 4(19), 5(23), 6(23), 7(22), 8(10), 9(20), 10(14), 11(19), 12(24), 13(22), 14(15), 15(19), 16(24), 17(22), 18(24), 19(23), 20(21), 21(5), 22(18), 23(23), 24(23), 25(23), 26(22), 27(17), 28(23), 29(22), 30(10) and 31(17) July 2025. (e) Dates with SO2 exceedances (number of exceedances on that day) were identified on 1(1), 2(5), 3(5), 4(1), 5(2), 6(3), 7(1), 9(1), 10(2), 17(1), 18(15), 19(13), 20(1), 22(4), 23(2) and 24(1) July 2025. (f) Dates with VOC exceedances (number of exceedances on that day) were identified on 1(2), 2(7), 3(6), 4(3), 5(5), 6(5), 7(1), 10(1), 11(2), 12(1), 14(2), 16(1), 17(2), 18(3), 19(4), 20(2), 21(1), 23(2) and 24(3) July 2025. (g) Dates with NH3 exceedances (number of exceedances on that day) were identified on 1(1), 2(11), 3(11), 4(6), 5(11), 6(6), 7(3), 8(1), 11(6), 12(1), 13(1), 14(5), 17(2), 18(2), 19(13), 20(3), 23(2), 24(2), 25(1), 26(1) and 31(8) July 2025. (h) Dates with HCl exceedances (number of exceedances on that day) were identified on 3(2), 5(2), 7(1), 17(1), 19(1) and 24(1) July 2025. (i) Dates with HF exceedances (number of exceedances on that day) were identified on 1(1), 2(2), 3(4), 4(1), 5(5), 6(4), 7(1), 11(1), 14(6), 15(1), 16(1), 17(1), 18(2), 19(9), 20(3), 22(5), 23(1), 24(7), 27(2), 28(1) and 31(4) July 2025. |

||||

Table 4.6 Hourly Average of Parameters Recorded for the Standby Flaring Gas Unit

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) (c) |

Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

Dust (or TSP) |

0 0 |

5 |

Nil |

Nil |

|

Carbon Monoxide |

0 3 |

100 |

Nil |

Nil |

|

NOx |

0 10 |

200 |

Nil |

Nil |

|

SO2 |

0 15 |

50 |

Nil |

Nil |

|

VOCs (including methane) (b) |

0 7 |

20 |

Nil |

Nil |

|

HCl |

0 0 |

10 |

Nil |

Nil |

|

HF |

0 2 |

1 |

Identified (c) |

System unstable (e.g. low efficiency) |

|

Notes: (a) All values refer to an oxygen content in the exhaust gas of 6% and dry basis. (b) The VOCs emission limit include methane as biogas is adopted as fuel in the combustion process. (c) Date with HF exceedance (number of exceedances on that day) were identified on 18(2) July 2025. |

||||

4.2 odour

4.2.1 OPERATION PHASE MONITORING

Odour patrol was conducted by the independent odour patrol team of ALS Technichem (HK) Pty Ltd on 15 July 2025. According to the EM&A Manual, it is considered an Action Level exceedance if the odour intensity recorded by the panellists is Level 2 or above. During the reporting period, two (2) Action Level exceedances (detection of Odour Intensity Level 2) were recorded during the independent odour patrol at Location 2 (near Tipping Hall) on 15 July 2025.

In accordance with the Event and Action Plan for Odour Monitoring (see Table 3.8), an ad-hoc odour patrol on 28 July 2025 was arranged by the Contractor to confirm the findings, which identified one (1) Level 2 exceedance at Location 2, consulting an exceedance of the Limit Level under the EM&A Manual. A further patrol was conducted in Round 2 with no exceedance identified. The odour patrol result for both regular and ad-hoc odour monitoring are shown in Annex G.

4.3

waste management

4.3.1 OPERATION PHASE MONITORING

Wastes generated from the operation of the Project include chemical waste, wastes generated from pre-treatment process and general refuse ([3]). Reference has been made to the Monthly Summary Waste Flow Table prepared by the Contractor (see Annex D). With reference to the relevant handling records and trip tickets of this Project, the quantities of different types of waste generated from the operation of the Project in the reporting month are summarised in Table 4.7.

Table 4.7 Quantities of Waste Generated from the Operation of the Project

|

Month / Year |

|||||

|

2.995 tonnes (e) |

|||||

|

Notes: (a) Waste generated from pre-treatment process and general refuse other than chemical waste and recyclables were disposed of at NENT Landfill by sub-contractors. (b) Among waste generated from pre-treatment process, no metals, papers/cardboard packing or plastics were sent to recyclers for recycling during the reporting period. (c) Among general refuse, 0.027 tonnes of papers/cardboard packing were sent to recyclers for recycling during the reporting period. No metals or plastics were sent to recyclers for recycling during the reporting period. (d) 8,000 L of chemical waste were disposed of at CWTC during the reporting period. (e) It was assumed that four 240-litre bins filled with 80% of general refuse were collected at each collection. The general refuse density was assumed to be around 0.15 kg/L. |

|||||

5.

site audit

5.1 environmental site audit

5.1.1 OPERATION PHASE

The monthly inspection for the operation phase of the Project on 29 July 2025 covered the operation phase environmental site audit. Joint site inspection was conducted by representatives of the Contractor, IEC, and the MT as required for the operation of the Project.

The audits checked the implementation of the recommended mitigation measures for air quality, landscape and visual, water quality, waste (land contamination) and hazard-to-life stated in the Implementation Schedule (see Annex C).

Key observations during the reporting period are summarised as follows:

29 July 2025

· No particular observation during this inspection.

The Contractor has implemented the environmental mitigation measures recommended in the approved EIA Report and EM&A Manual.

6.

environmental non-conformance and deficiencies

6.1 summary of environmental non-compliance

and deficiencies

Non-compliance of emission limits of Total Odour from CAPCS; NOx and SO2 from CHP1; NOx from CHP2; NOx from the CHP3; CO, NOx, SO2, VOC, NH3, HCl and HF from ASP and HF from Standby Flaring Gas Unit were recorded during the reporting period.

The Contractor has reviewed the organic waste treatment processes (i.e. waste reception, waste pre-treatment, anaerobic digesters, and composting processes) and found that they were operated normally during the reporting period. The Contractor has investigated the de-sulphurisation system, the CHPs, the ASP and the Standby Flaring Gas Unit; the potential causes for the exceedance were identified.

Two Action Level exceedances (detection of Odour Intensity Level 2) at Location 2 were recorded during the odour patrol in the reporting period. One ad-hoc odour patrol on 28 July 2025 was arranged to confirm the findings with one Level 2 exceedance being identified at Location 2 during Round 1. A further patrol was conducted in Round 2 with no exceedance identified.

The investigation reports of the above exceedances are presented in Annex F.

To address the continuous exceedances at Cogeneration Unit 1 to 3 (CHP1 to 3), additional advanced training from the manufacturer for the operation and maintenance of the equipment had been completed. The Contractor has further identified that a buildup of silicon deposits on the cylinder heads of the CHPs is preventing the engines from reaching full loading. Routine maintenance including cleaning has been carried out by the Contractor.

To address the ongoing exceedances at Ammonia Stripping Plant (ASP), overhaul of the ASP was conducted and visit by the supplier was completed. Fine tuning has been conducted by the Contractor to improve the performance.

6.2 summary of environmental complaint

No complaint was received during the reporting period.

6.3 summary of environmental summon and

successful prosecution

No summon/ prosecution was received during the reporting period. The cumulative summons/ prosecution log is shown in Annex E.

7.

future key issues

7.1 key issues for the coming month

Activities to be undertaken for the coming reporting period are:

· Implementation of various optimization measures in wastewater treatment plant.

8.

conclusions

This EM&A Report presents the EM&A programme undertaken during the reporting period from 1 to 31 July 2025 in accordance with the EM&A Manual (Version F) and requirements of EP (FEP-01/395/2010/C).

For the operation phase, exceedances of the emission limits for the CAPCS, CHPs, ASP and the Standby Flaring Gas Unit were recorded under normal operating conditions during the reporting period (see Table 8.1).

Table 8.1 Exceedances for Stack Emissions

|

Stack |

Exceedances During the Reporting Period |

|

|

CAPCS |

· Exceeded emission limits of Total Odour on 18, 19, 20, 21, 22, 23, 24, 25, 26, 27 and 30 July 2025. |

|

|

Cogeneration Unit 1 (CHP 1) |

· Exceeded emission limit of NOx on 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 22, 23, 24, 25, 26, 27, 28, 29, 30 and 31 July 2025. · Exceeded emission limit of SO2 on 18 July 2025. |

|

|

Cogeneration Unit 2 (CHP 2) |

· Exceeded emission limit of NOx on 1, 2, 22, 27 and 28 July 2025. |

|

|

Cogeneration Unit 3 (CHP 3) |

· Exceeded emission limit of NOx 1, 2, 3, 4, 5, 6, 7, 8, 12, 13, 17, 18, 19, 22, 23, 24, 25, 26, 27, 28, 29, 30 and 31 July 2025. |

|

|

Ammonia Stripping Plant (ASP) |

· Exceeded emission limit of CO on 1, 2, 3, 4, 5, 6, 7, 10, 12, 14, 17, 18, 19, 20, 23 and 24 July 2025. · Exceeded emission limit of NOx on 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30 and 31 July 2025. · Exceeded emission limit of SO2 on 1, 2, 3, 4, 5, 6, 7, 9, 10, 17, 18, 19, 20, 22, 23 and 24 July 2025. · Exceeded emission limit of VOC on 1, 2, 3, 4, 5, 6, 7, 10, 11, 12, 14, 16, 17, 18, 19, 20, 21, 23 and 24 July 2025. · Exceeded emission limit of NH3 on 1, 2, 3, 4, 5, 6, 7, 8, 11, 12, 13, 14, 17, 18, 19, 20, 23, 24, 25, 26 and 31 July 2025. · Exceeded emission limit of HCl on 3, 5, 7, 17, 19 and 24 July 2025. · Exceeded emission limit of HF on 1, 2, 3, 4, 5, 6, 7, 11, 14, 15, 16, 17, 18, 19, 20, 22, 23, 24, 27, 28 and 31 July 2025. |

|

|

Standby Gas Flaring Unit |

· Exceeded emission limit of HF on 18 July 2025.

|

|

Two Action Level exceedances (detection of Odour Intensity Level 2) at Location 2 were recorded during the odour patrol in the reporting period. An ad-hoc odour patrols on 28 July 2025 were arranged to confirm the findings with one Level 2 exceedance being identified at Location 2 during Round 1. A further patrol was conducted in Round 2 with no exceedance identified.

No complaint was received during the reporting period.

The Contractor has reviewed the organic waste treatment processes (i.e. waste reception, waste pre-treatment, anaerobic digesters, and composting processes) and found that they were operated normally during the reporting period. The Contractor has investigated the de-sulphurisation system, the CAPCS, CHPs and the ASP; the potential causes for the exceedances were being identified.

The environmental control/ mitigation measures related to air quality, water quality, waste (including land contamination prevention), hazard-to-life and landscape and visual recommended in the approved EIA Report and the EM&A Manual were properly implemented by the Contractor during the reporting month.

([1]) A standby facility; only

operates when the CHPs are not in operation or when the biogas generated

exceeded the utilisation rate of the CHPs.